The Role of 3D Printing in Future Manufacturing

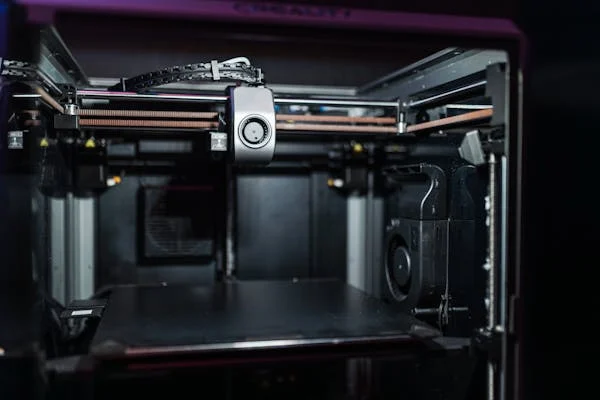

3D printing, also known as additive manufacturing, is transforming the way products are designed, prototyped, and produced. From aerospace and healthcare to automotive and consumer goods, industries are rapidly adopting this technology to improve efficiency, reduce waste, and enable mass customization. As the technology advances, 3D printing is set to play a crucial role in the future of manufacturing, offering innovative solutions that traditional manufacturing methods cannot match.

How 3D Printing is Changing Manufacturing

Faster Prototyping and Product Development

Traditional prototyping methods can be expensive and time-consuming, requiring molds, machining, and assembly. 3D printing allows for rapid prototyping by creating physical models directly from digital designs. This enables manufacturers to test and refine products faster, reducing development time and bringing innovations to market more quickly.

Customization and Personalization

One of the most significant advantages of 3D printing is its ability to produce customized products without additional tooling costs. This is especially useful in industries like healthcare, where patient-specific implants, prosthetics, and dental aligners can be tailored to individual needs. Similarly, in consumer goods, personalized accessories, footwear, and even custom furniture are becoming increasingly popular.

Reduced Material Waste and Sustainability

Unlike subtractive manufacturing, which involves cutting away material from a solid block, 3D printing builds objects layer by layer. This process minimizes material waste, making it a more sustainable option. Additionally, many companies are exploring the use of recycled materials, biodegradable filaments, and bio-based resins to further enhance sustainability.

Cost Savings and Supply Chain Optimization

By reducing the need for large inventories and on-demand production, 3D printing can streamline supply chains and lower storage costs. Companies can manufacture parts locally rather than relying on overseas production, reducing transportation expenses and carbon footprints. This decentralized approach to manufacturing is expected to reshape global supply chains in the coming years.

Complex Geometries and Lightweight Structures

3D printing enables the creation of complex designs that would be impossible or highly expensive to produce using traditional manufacturing techniques. This is particularly beneficial in aerospace and automotive industries, where lightweight components can significantly improve fuel efficiency and performance. Lattice structures, hollow components, and organic shapes can be easily fabricated using additive manufacturing.

Future Trends in 3D Printing

Multi-Material and Multi-Color Printing

Advancements in 3D printing are allowing the use of multiple materials within a single print. This opens doors for more functional and aesthetically appealing products, such as electronics with embedded circuits or bio-compatible implants with different material properties.

Large-Scale 3D Printing in Construction

3D printing is making its way into the construction industry, with companies developing large-scale printers that can fabricate entire buildings. This has the potential to reduce construction costs, speed up housing projects, and create sustainable structures using eco-friendly materials.

Bioprinting and Medical Applications

In the medical field, 3D bioprinting is being explored to print tissues, organs, and skin grafts using living cells. While still in the research phase, this technology could revolutionize organ transplantation and regenerative medicine in the future.

Conclusion

3D printing is no longer just a niche technology—it is becoming a core part of modern manufacturing. As innovations continue to emerge, its impact will expand across industries, enabling smarter, more sustainable, and more efficient production methods. From personalized products to large-scale industrial applications, the future of manufacturing is undoubtedly being shaped by the endless possibilities of 3D printing.

.png)

Leave a Comment

Your email address will not be published. Required fields are marked *