The Role of Simulation in UAV Structural Optimization

Unmanned Aerial Vehicles (UAVs) are rapidly evolving in both military and civilian applications, necessitating advanced design techniques to enhance performance, durability, and efficiency. One of the most crucial aspects of UAV development is structural optimization, which involves refining the aircraft’s framework to achieve the best strength-to-weight ratio. Traditional prototyping methods can be expensive and time-consuming, making simulation-based structural optimization an essential approach for UAV engineers.

Importance

of Structural Optimization in UAVs

Structural

optimization ensures that UAVs achieve high performance while maintaining

lightweight structures. This is critical because excess weight affects fuel

efficiency, flight endurance, and maneuverability. Through advanced simulation

techniques, engineers can design UAV components that are both strong and

lightweight, ensuring superior performance in real-world conditions.

Role

of Simulation in UAV Structural Optimization

Simulation

plays a pivotal role in structural optimization by enabling engineers to

predict how UAV structures will respond to various forces and environmental

conditions. Some key areas where simulation proves beneficial include:

1.

Finite Element Analysis (FEA)

FEA

is a computational method used to evaluate stresses, strains, and deformations

in UAV structures. By applying load conditions in a virtual environment,

engineers can identify weak points and reinforce them without physically

testing multiple prototypes.

2.

Computational Fluid Dynamics (CFD)

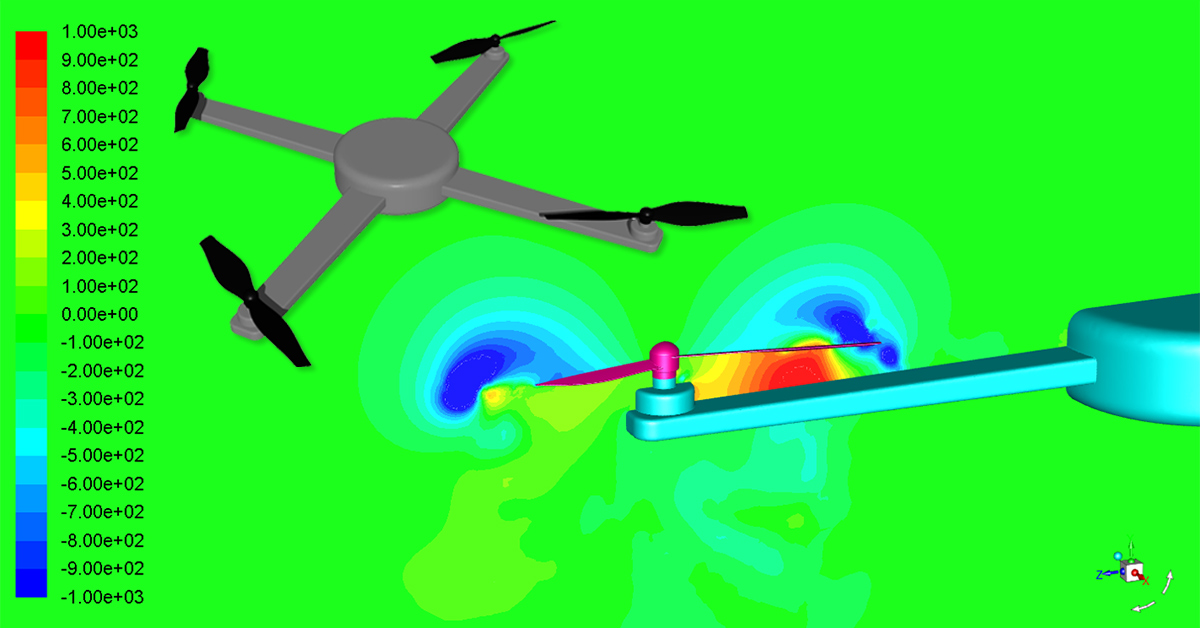

CFD

simulations help optimize UAV aerodynamics by analyzing airflow, pressure

distribution, and drag forces. This ensures that structural changes do not

negatively impact the UAV’s aerodynamic efficiency.

3.

Multiphysics Simulations

Advanced

UAV designs often involve integrating mechanical, thermal, and aerodynamic

factors. Multiphysics simulations allow engineers to assess how these factors

interact, leading to better material selection and structural modifications.

4.

Fatigue and Failure Analysis

UAVs

are exposed to continuous stresses during flight. Simulation tools can predict

fatigue life and failure points, helping designers improve the longevity of UAV

components through better material choices and reinforcement techniques.

5.

Topology Optimization

Topology

optimization algorithms help in designing structures that maximize strength

while reducing unnecessary material. This is particularly useful in additive

manufacturing, where lightweight and structurally efficient UAV components can

be 3D-printed based on simulation results.

Advantages

of Using Simulation for UAV Structural Optimization

Simulation

provides several significant advantages for UAV structural optimization. It

helps reduce costs by minimizing the need for multiple physical prototypes,

saving both time and resources. By ensuring optimal weight distribution,

simulation enhances overall performance, leading to better fuel efficiency and

improved flight capabilities. Engineers benefit from rapid design iterations,

as they can quickly test and refine structural modifications based on

simulation results. Additionally, simulation tools help mitigate risks by identifying

potential failure points before real-world deployment, thereby enhancing UAV

safety and reliability. Overall, simulation plays a critical role in optimizing

UAV structures, making them more efficient, durable, and cost-effective.

Conclusion

Simulation-based

structural optimization is revolutionizing UAV development by providing

precise, data-driven insights into material selection, aerodynamic performance,

and overall durability. As UAV technology continues to advance, integrating

cutting-edge simulation techniques will be essential for designing efficient,

lightweight, and high-performance aerial vehicles. By leveraging tools such as

FEA, CFD, and topology optimization, engineers can push the boundaries of UAV

innovation while reducing costs and improving reliability.

.png)

Leave a Comment

Your email address will not be published. Required fields are marked *